Over the last decade, there has been a sharp rise in the number of microbreweries in the United States. It’s a growing market with 8,764 brew houses in 2020—a rise from 1,409 in 2006.*

Like any facility where food or beverages are produced, brewery flooring needs to be long-lasting, hygienic, and robust enough to withstand any spills of liquids, yeasts, or chemicals associated with the brewing process.

Whether you run an established brewery or are just starting out with a family-based brewing business, it’s important to install the right flooring the first time. Read on to discover how Everlast® Epoxy floors can deliver durable brewery flooring that’s sanitary and safe.

Spillages are not a problem

It’s almost impossible to run a brewery without spilling some beer! With many flooring solutions, such as concrete or tiles, any spillages will soak into the substrate and cause damage, creating a haven for bacteria and bad odors.

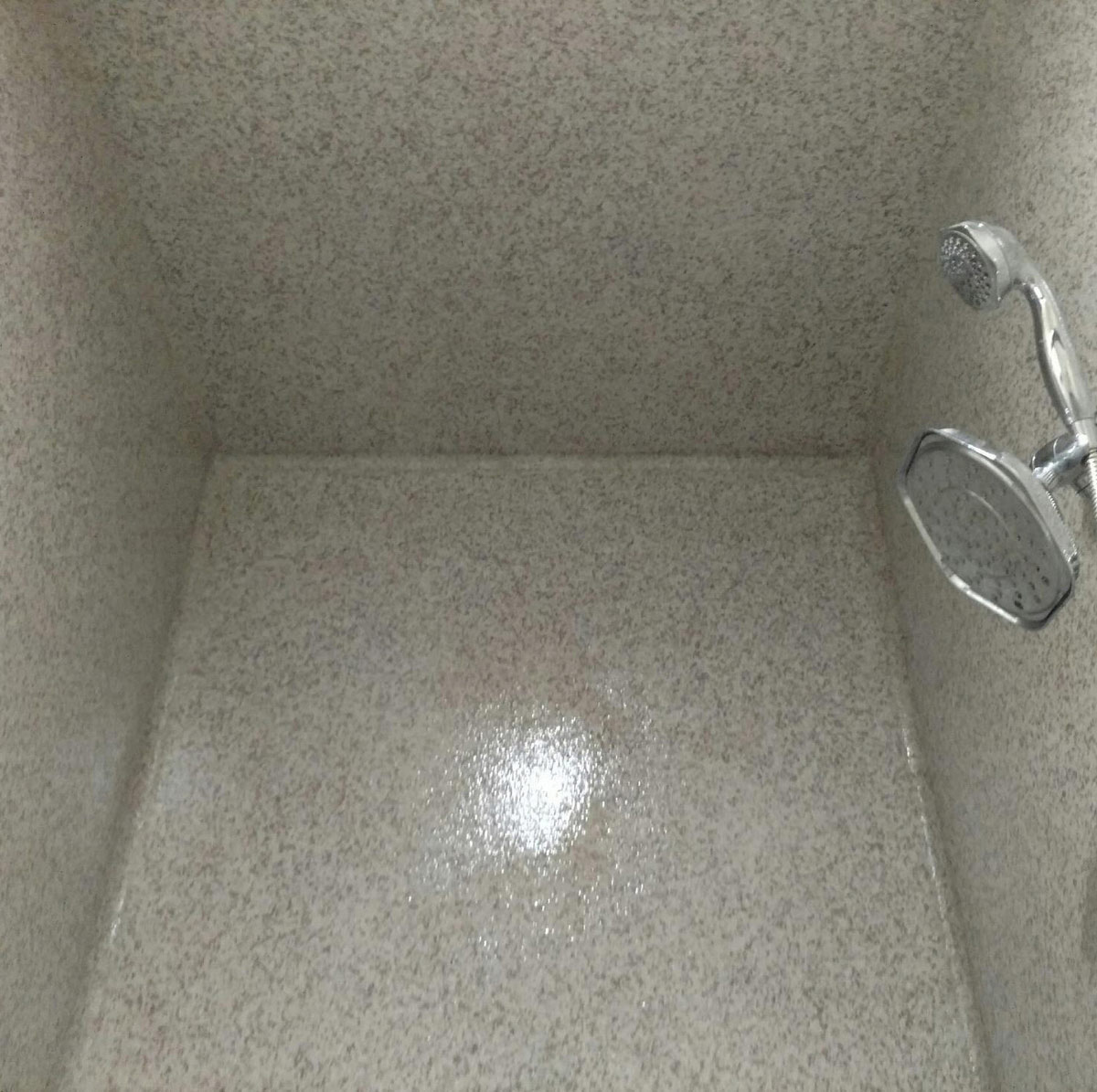

An Everlast® Epoxy resin floor provides a continuous, waterproof, and seamless surface with no joints. Our flooring is created using a tightly bonded compound that does not allow liquids to seep through and cause deterioration of the substrate.

A waterproof floor means that spillages can simply be wiped away from the surface—you don’t need to worry about liquids penetrating through the layers and creating an unsanitary environment.

A hygienic environment for beer production

Everlast® Epoxy flooring contains an EPA-registered antimicrobial additive that impedes the growth of microorganisms, providing your brewery floor with long-lasting protection against bacteria, germs, yeast, and mildew.

Many epoxy flooring suppliers claim that their floors are antimicrobial, but the reality is that they use an antimicrobial agent in the sealer applied as a topcoat. This means that any gouges or scratches to the surface can be an open invitation for microorganisms to penetrate the layers underneath and cause damage.

Protecting your floors against microorganisms also helps create a safer working environment. With less mold and bacteria in the air, staff and visitors are at less risk from respiratory issues.

Heat- and chemical-resistant brewery flooring

The brewing process involves heat and high temperatures, so it’s important to choose a floor that can withstand extreme temperatures.

With an Everlast® Epoxy floor, you’ll never have to worry that your flooring system isn’t up to the job. Our floors are able to repeatedly withstand temperatures of up to 158°F without any detrimental effect on the surface.

Beer is also acidic, and over time will slowly corrode a concrete surface and cause the failure of the floor.

Our flooring is also resistant to many harsh chemicals, including acids, and shows no sign of pitting, cratering, or erosion—even after the floor has been fully saturated in over thirty chemical compounds for seven days and nights.

Brewery flooring that is a breeze to maintain

A poor maintenance routine will have a negative effect on any floor, so we’ve designed our resin floors to be easy to clean and maintain with minimal effort. Our Everlast® Epoxy cleaning products will clear the floor of dirt, grime, and harsh chemicals, which can then be simply rinsed away down the nearest drain.

By following this simple upkeep routine, your brewery floor will provide years of service without any back-breaking and time-consuming work—no scrubbing, buffing, or polishing required.

Anti-slip properties

Any wet production environment can be hazardous for staff, so keeping the brewery workforce safe is the number one priority for any reputable brewing house.

Our epoxy resin floor has a textured finish, which gives enhanced slip resistance to the surface of the flooring.

If you intend to install flooring in a wet production environment, we also offer the option for an additional layer of grit that is applied to the glaze coat to create a sandpaper-like finish to help protect your staff from trips and falls.

Speak to the experts before your choose a brewery floor

We understand that something as mundane as your flooring can be easily sidelined, but by starting with a durable and safe system, you can expect many years of reliable service from your brewery floor.

If you are ready to speak to our experts about installing a healthy and long-lasting brewery floor, contact us at (800) 708-9870 or fill in our inquiry form online.